Frequently Asked Questions

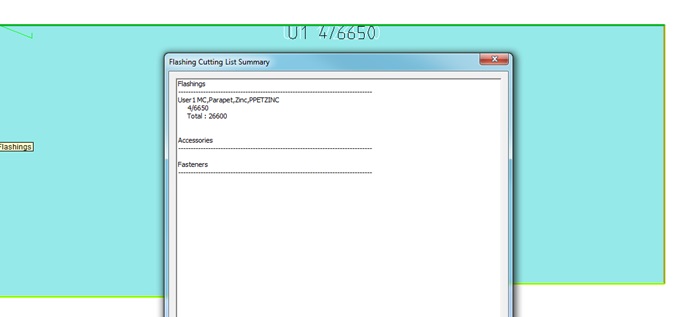

How to get “custom flashings” to split order lengths up to the maximum length?

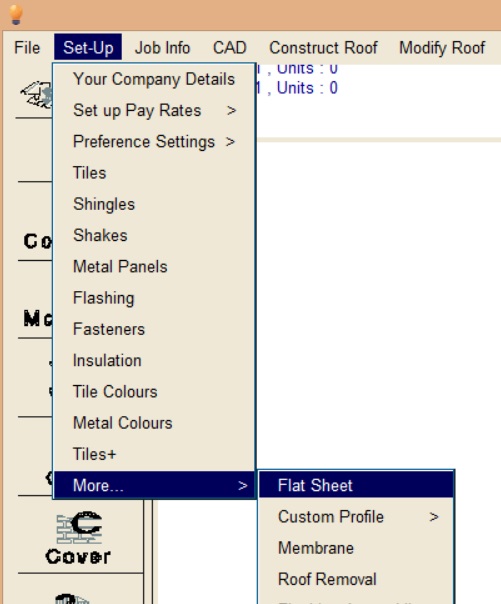

When you select your Custom Profile flashing, (Cover > Flashings) you are prompted to select the flat-stock from which your custom trim will be fabricated. The flat-stock is defined via the Set Up > More > Flat Sheet menu option. This is where you set up all the parameters that control the use of flat-stock for fabricating into a custom flashing item, including cost per number of bends, for increments of stretch out or girth and the estimating options (cut to length or stock length).

To set the estimation method go to Set Up > More > Flat Sheet.

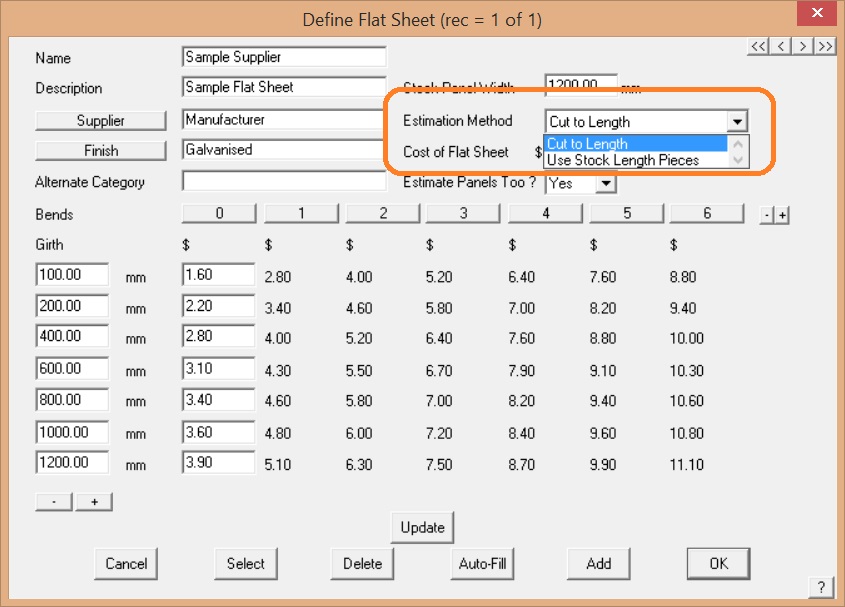

Switch the estimation method from 'Cut to Length' to use 'Stock Length Pieces'.

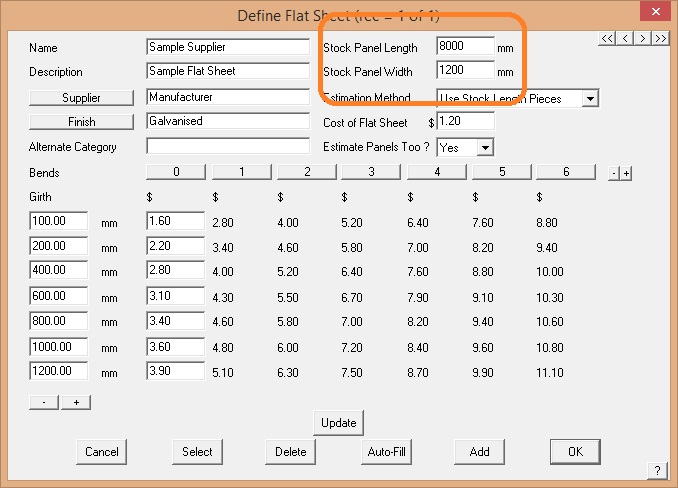

Once it’s set to Stock Length Pieces you get the Stock Panel Length box - put your maximum length in there, say 8000mm in our example. Check that your Stock width is set correctly as the software will automatically figure out how many trim pieces can be made from each piece of flat stock and count total number of flat stock pieces from inventory.

Then switch it back to Cut to Length and when you use a custom flashing using that same flat-stock name, you should get it split into the lengths.

back