BIM – or Why Bother With a 3D Model for Estimating?

I expect a lot of people have heard about BIM – Building Information Modelling. It is all the rage lately and is making a lot of difference to the way designers are documenting their projects.

Basically, what it means is that instead of being a collection of lines and points, all design elements in a 3D model structure can be autonomous (for example windows and doors), and they have additional information stored with the element. Any change to the element is automatically reflected everywhere it is represented in the 3D model and to subsequent construction documents. This is very useful to all concerned.

This process is not new or innovative, for AppliCad has been incorporating additional information into each roof model since we started this journey nearly 30 years ago.

AppliCad pioneered the 3D CAD model approach in roof estimating

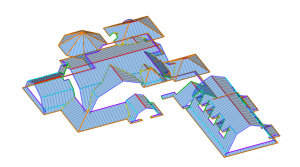

In fact, AppliCad was the first company in the world to employ a 3D CAD model as the basis for estimating roofing materials. We were drawn to this approach because the CAD model was like having a digital prototype of the roof. We were reproducing the roof geometry using dimensions provided by the architect or from field measurements and if the measurements were incorrect, it became immediately apparent.

If we couldn’t construct the geometry in 3D in CAD, then it was most likely that the roof shape could not be built for real. This provided a very valid first check before a detailed estimate was produced. You might think of it as a ‘dress rehearsal’ for the roof. The model we create is full size, using actual dimensions, so now this provides us with the ability to report instantly the basic information that every estimator or quantity surveyor needs – areas and lengths.

AppliCad does not stop at area and lengths

Apart from the ability to confirm that the geometry works, the real strength of AppliCad’s 3D roof model is the attributes we apply to all the roof features – the roof plane knows what the material category is going to be – tiles, shingles, metal etc, and each edge of the roof knows what it is in the context of the roof – ridge, hip, gable, etc.

With this information, we have been able to generate very accurate material take-offs because in addition to length, each line knows what material needs to be installed and with that material, the exact accessory items and labour cost to install, right down to corner treatments, internal and external corners are identified. A detailed quotation is just so easy when all the information is automatically applied based on the model geometry. It is the most efficient AND the most accurate way to cost a job and extract a detailed material list and labour summary.

After a few years, it became apparent that we needed to do estimating for wall cladding as well, especially for commercial structures. However, there is a trend currently for metal cladding to be used on residential walls, so we are now doing roof and walls on a regular basis using the exactly the same approach.

So why use Roof Wizard for estimating? It is a dress rehearsal for the real gig and ensures accuracy, efficiency and profitability. Do in hours what used to take days. With our software successfully used in 148 countries, we’re doing it right.