Congratulations on your purchase of a New Tech Machinery NTM Roll Forming machine. With it, you will have been informed about AppliCad software as the perfect software tool to get the most out of your investment. This page will give you more information about how AppliCad will help you get the most out of AppliCad and NTM Roll Former.

Here is how AppliCad Roof Wizard turbocharges your NTM Rollformer

If you are new to metal roofing, you will notice that business processes are slightly different as compared to other roofing systems. Rather than estimating and ordering materials by “squares”, we think that you must be more specific than that – to avoid material waste, for each and every job. That is where AppliCad software comes in.

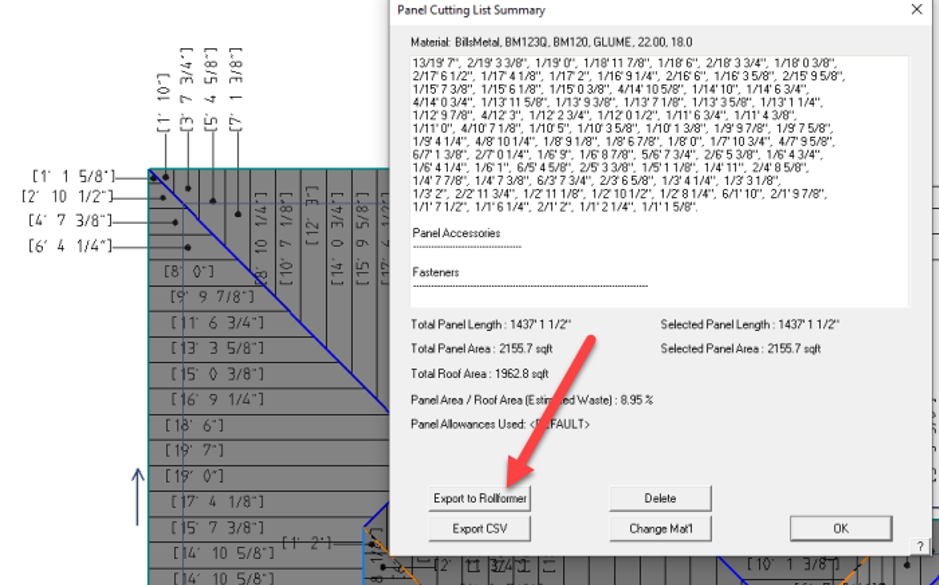

Thanks to the fact that you can model the roof on your computer with its exact dimensions, the software calculates exact quantities based on the application of panels to the roof model – simulating the installation process. The software generates a panel cutting list taking account of installation allowances, and feeds optimised panel cutting details directly into your NTM roll former control panel.

Accuracy is paramount in metal roofing

With AppliCad Roof Wizard software, your customer service team prepares the client’s quotation for the supply and installation of their new metal roof. The quotation is very accurate (and accurate in AppliCad’s world means +/- fractions of an inch if required) because it is based on the 3D CAD model of the roof, constructed using your own measurements and the simple modelling tools in the AppliCad Roof Wizard.

“Sheet metal is not like shingles or tiles. You cannot take extra coil back to the supplier, so you better get it right from the start…”

Because the 3D roof model has been checked (compared to site verification) and is correct, the cutting list is correct and when sent to the controller of your roll forming machine, there is no ‘keying in’ of panel length numbers, there are no errors. Seamless 100% accuracy – totally integrated from quotation to delivery and installation. The total length of coil is also calculated so that you have ordered the correct material quantity for each job.

Productivity gains right into the details of a job

All installation allowances such as gap at the hip and ridge, offset from the valley and overhang into the gutter, including allowance for the hem have been automatically accounted for in the final cutting list and coil length calculation.

When you use New Tech Machinery and AppliCad you get the right results.

It’s almost like 1+1=3!

You even have options to

- specify rounding lengths to whole numbers,

- setting the panel start point,

- aligning panels with adjacent roof planes, etc.

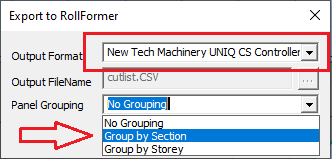

AppliCad software works the way you do. Simply select [Export to Rollformer] and click on the New Tech Machinery output file format and save it to a thumb drive and you’re ready to go:

Watch this video to see AppliCad software in action

Watch how to export a cutting list in AppliCad.

Want to learn more?

Read more about metal roofing here.

Contact us today if you have any questions: ray.smith@applicad.com